Most versatile process for shape cutting.

When flame, plasma, laser, wire cutting and milling, fail to produce the parts as desired then it is a simple decision to opt for waterjet cutting. Safeguard’s waterjet cutting process for your parts can provide a more detailed finish product than heat cutting or milling.

Why Should You Utilize Water Jet Cutting?

No Heat

- No slag or burr means excess grinding / finishing isn’t necessary

- Heat treatment conditions are not affected.

- Avoidance of micro-cracking or distortion of cut materials

Improved Material Usage

- Nesting & In-Line Cutting allows for more usage for sheet material

- Cut quality eliminates defective parts

- Near net shapes are generated

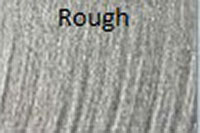

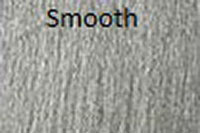

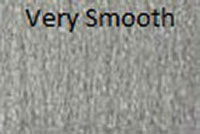

Better Cut Quality

- Ability to achieve sharp inside corners

- Clean holes eliminate deburring

- Pinpoint contouring to perfectly match the needed cut

Our Process

Safeguard Waterjet offers 24/7 water jet cutting availability with state-of the art water jet cutting equipment on hand. Our goals is to quickly identify your cutting challenges, plan a course of action, and get your materials processed and back in your hands as quickly as possible.

Cutting Services

- Fixed Price (Long or Short Run)

- Annual Contracts

- Cutting Cost Optimization

Materials For Water Jet Cutting

Abrasive Jet:

- Reactive Metals: Titanium, Zirconium, Tantalum, and Niobium

- Nickel-Based Alloys: Inconel, Nickel, Hastelloy

- Stainless Steel & Carbon Steel

- Aluminum, Brass, & Copper

- Composites, Plastics, Rubber, & Ceramics

- Bonded Multi-Materials:

- Clutch Plates & Brakes

- Rubber-on-Metal

- Explosion Bonded & Roll Bonded Materials

- Heat Treated Metals 35-55 RC

Water Only:

- Cured Rubber, 30-90 Durometers

- Plastics, Fiberglass, PVC, Graphite and some Glass

- Food Product Equipment

- Corrugated Paper Products

CAD & CAM Services

Safeguard Waterjet can coordinate precise modeling of you product design in a variety of different software’s including: AutoCAD DXF, IGES, and SigmaNEST.

- Shapes are cut directly from client files or files produced internally

- Minimal redrawing, error reduction, and traceability is withheld.

- Engineering changes can be made promptly

- Files can be transferred via modem, DNC links, or networks